Continue reading

Continue reading

Automotive & Heavy Plant

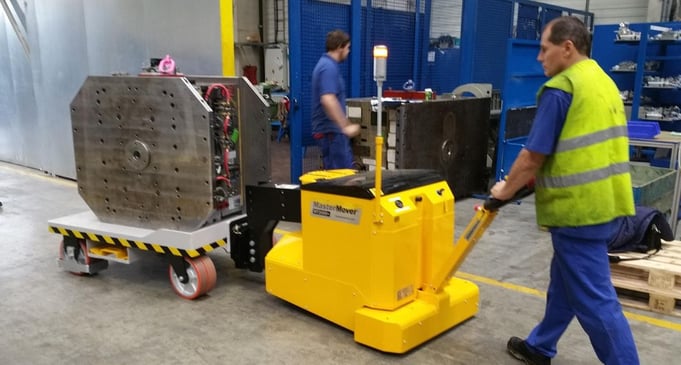

Automotive and heavy plant machinery manufacturers use MasterMover electric tugs to enhance lean processes and increase shop floor flexibility.

Whether it’s in the lineside delivery of parts or the transfer of heavy sub-assemblies, electric tugs maximise production efficiency and reduce downtime.

Thank you for submitting your demo request.

A member of the team will be in touch shortly.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Sectors we work in

Working across the automotive and heavy plant manufacturing industry, global manufacturers trust electric tugs to drive operational efficiency, optimise production processes and enhance workplace safety.

-

Automotive & commercial vehicles

-

Automotive supply chain

-

Heavy Plant

-

Engine, pump and generator

-

Trailer manufacturing

-

Tyre manufacturing

Automotive & commercial vehicles

Shifting efficiency up a gear

Automotive and commercial vehicle OEMs depend on electric tugs to maximise efficiency in the movement of body-in-whites, press tools, parts and kitting trolleys. Eliminating manual handling and reducing the dependency on forklift trucks in internal processes enables automotive manufacturers to unlock greater efficiency and create leaner production lines.

Automotive supply chain

Optimising automotive supply chain efficiency

Our innovative material handling equipment is trusted across the automotive supply chain to reduce bottlenecks and streamline processes – ensuring production keeps moving. Relied on by leading automotive tier 1 and tier 2 suppliers, electric tow tugs deliver the safe, efficient movement of parts, components and equipment. Enabling the just-in-time movement of loads, electric tugs help you maintain credibility and commitment to your automotive manufacturing customers.

Heavy Plant

Maximum flexibility to meet demand and reduce costs

Increased demand, supply chain pressures and large, cumbersome loads continue to put pressure on heavy plant machinery manufacturers. To create flexible, scalable processes that reduce downtime and maximise production output, heavy plant manufacturers choose electric tugs – compact machines that deliver the controlled movement of 30,000kg loads and beyond.

Engine, pump and generator

Heavy-duty solutions for powerful movements

Within the manufacture of engine, pump and generators, rapid evolution across the industry is powering the focus on production efficiency and agility, with manufacturers looking to reduce wasted time and create leaner processes. Leading manufacturers trust MasterMover electric tugs to create flexible production processes and deliver the controlled movement of heavy-wheeled loads in confined spaces.

Trailer manufacturing

Reducing downtime in trailer movement

For trailer manufacturers, improving workflows and streamlining processes is key. However, many manufacturers still rely on a combination of shunters, forklift trucks and lorry cabs to transfer completed trailers off the line. Our electric Trailer Moving System makes light work of unladen trailers weighing up to 20,000kg with zero emissions. Perfectly suited for tight production areas and to deliver maximum visibility and smooth, controlled movement.

Tyre manufacturing

Eliminating manual handling to accelerate efficiency

Global tyre manufacturing facilities trust MasterMover electric tugs to eliminate manual handling and boost production efficiency. Whether it’s in the movement of cassette trolleys, bead racks or even tread trolleys, electric tugs enable a single operator to effortlessly move heavy-wheeled loads, maximising safety and empowering operators to focus on greater value-adding tasks.

The benefits for automotive and heavy plant industries

Manufacturers in automotive and heavy plant industries trust MasterMover electric tow tugs to deliver the safe, controlled movement of wheeled loads.

Thank you for submitting your demo request.

A member of the team will be in touch shortly.

-

Accelerating operational efficiency

A license-free operation reduces bottlenecks and drives operational efficiency, empowering staff to focus on value-adding tasks.

-

Creating safer, fork-free zones

Electric tugs empower manufacturers to reduce their reliance on forklift trucks in congested areas – improving workplace safety and reducing the risk of accidents.

-

Keeping your people safe

Alongside reducing forklift traffic in production environments, electric tow tugs help manufacturers improve workplace safety by eliminating the need for manual handling.

-

Controlled movement of 70,000kg in tight areas

Powerful performance and intuitive controls guarantee the controlled movement of heavy, high-value loads – even in congested production environments.

Trusted by industry heavyweights

Leading global automotive and heavy plant manufacturers trust MasterMover electric tugs to boost production efficiency and maximise workplace safety.

AGV Systems – Case Study

Toyota accelerates efficiency with an AGV system

A world leader in its field, the automotive manufacturer has achieved return on investment and improved operational efficiency when moving parts to the production line…

Learn how Toyota Motor Manufacturing used an AGV system to automate its driving processes.

Ready to Unlock Safer Operations?

Are you looking to improve safety and efficiency in your operations? Contact us to discover how you could transform your processes to enhance efficiency and maximise workplace safety with an electric tug or electric tow tug.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

Six New Models Expand the PowerSteered Range for Fingertip Control