Continue reading

Continue reading

Construction, Mining & Agricultural Electric Tugs

Thank you for submitting your demo request.

A member of the team will be in touch shortly.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Typical heavy plant equipment applications

For machinery manufacturers involved in manufacturing some of the heaviest equipment, material handling can be challenging. Whether it’s tracked excavators or combine harvesters, we help heavy machinery manufacturers move loads such as:

- Sub-assemblies & work-in-progress

- Booms & arms

- Chassis, frames & cabs

- Sheet metal & profiles

- Power systems, engines & powertrains

- Kitting trolleys

- Jigs, tooling & fixtures

- Axles, wheels & track units

Electric tug benefits in heavy plant assembly

Reduce takt time

Streamlining the movement of heavy loads, electric tugs create leaner processes and reduce downtime.

Heavy-weight power

Handle the heaviest loads with weight capacities up to 70,000kg and beyond

Increase throughput

Cut wasted time out of your material movement to drive efficiency

Create flexible processes

Move loads just-in-time to unlock agile and flexible processes

Our range of construction, mining & agricultural tugs

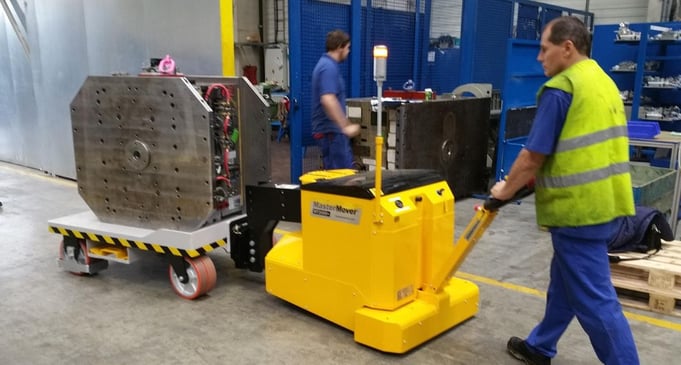

Our construction, mining & agricultural tugs in action

Solutions for today and tomorrow

Moving heavy equipment can slow production. Manufacturers of agricultural, construction, and mining machinery often rely on forklifts, cranes, and winches - leading to bottlenecks and downtime.

To keep production moving and reduce forklift dependency, they’re turning to more flexible solutions like electric tugs. A range of control options are available to meet every load moving challenge.

- Pedestrian operated - a single operator can safely manoeuvre even the heaviest loads with ease.

- Remote control operation - delivers maximum visibility by allowing operators to take up the ideal vantage point when moving large loads.

- Automated AGV electric tugs – unlock fully automated material movements to maximise efficiency, throughput, and labour utilisation.

Case study

Terex creates forklift-free processes with heavy-duty electric tugs

We supported Terex in reducing forklift traffic on their shop floor with our remote-controlled PS3000+ electric tugs. Enhancing safety and flexibility, the PS3000+ delivers exceptional manoeuvrability for handling 18,000kg rock-crushing chambers and sub-assemblies.

Trusted by industry heavyweights

Global agricultural, construction and mining equipment manufacturing facilities trust MasterMover’s powerful, compact electric tugs to make the movement of wheeled loads safer and more efficient.

The engineering innovation of the tugs, which use traction to distribute weight to the machine, is ingenious and means that a single pedestrian operator can move a stillage.

Martin BrindleyHealth & Safety Manager, JCB Hydraulics Business Unit

Why choose MasterMover?

- The world's leading manufacturer of electric tugs for over 25 years

- Over 40+ electric tugs to choose from

- Trusted by the world's leading heavy plant manufacturers

- Choose from innovative technologies and control modes

- In-house custom engineering capabilities

- Winner of the King's Award for Innovation 2023 & Queen's Award for International Trade 2021

- Global sales and support

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Your Questions, Answered - FAQs

No, unlike lifting equipment such as forklift trucks and cranes, an electric tug does not require a license to operate. A license-free operation reduces downtime and maximises operational efficiency, reducing wasted time waiting for a licensed driver.

Minimal training is required to safely operate an electric tug and we offer training packages to suit every requirement.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving.

Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

Six New Models Expand the PowerSteered Range for Fingertip Control