Rethinking Material Handling in Manufacturing with Industrial Tugs

Material Handling

In this blog, we outline the crucial role that electric material handling tugs play and discuss how they help manufacturers create safer, more efficient material handling workflows.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

A Changing Material Handling Landscape Demands Flexibility

In modern manufacturing processes, efficient material handling stands as the cornerstone to operational success. The movement of components, work-in-progress (WIP) and finished products all make up a collection of essential processes as part of production, manufacture and assembly operations.

Over the years, the landscape of material handling equipment has evolved, spurred by advancements in engineering and automation and an increasing need for flexibility. Amidst this, material handling tugs have emerged as indispensable tools within manufacturing, enabling the just-in-time movement of wheeled goods, parts and components.

What are Industrial Tugs?

Industrial tugs, sometimes referred to as electric tugs, electric tow tugs, motorised electric tugs or pedestrian tugs, are compact battery-powered machines designed to move heavy loads on wheels - like trolleys or dollies. This can include raw materials, high-value equipment and other resources in an industrial environment, in or around a production line or process, or in sectors such as retail, logistics, facilities management and more.

The Benefits of Material Handling Tugs

Electric tugs play a crucial role in improving material flow within manufacturing facilities, leading to streamlined operations and increased efficiency. One of the main benefits of using tugs and tow tugs is their ability to optimise workflows.

Unlike manual handling or forklift trucks, industrial tugs offer precise control and manoeuvrability, facilitating smoother transitions between workstations and assembly lines. This improved flow reduces cycle times, minimises downtime, and boosts overall throughput. Electric tow tugs can tow multiple loads simultaneously, enhancing their efficiency further. By consolidating multiple trolleys into a single train, they maximise payload capacity while minimising the need for extra resources or labour. This capability accelerates operations and reduces the risk of congestion within the facility.

Example Applications of Industrial Electric Tugs in Manufacturing

Within the manufacturing industry, the applications for material handling tugs are diverse, but principally, tugs are used to either:

- Support production processes

- Power the assembly line

Applications where industrial tugs are used to support the production process include examples such as:

-

Towing Mother and Daughter Carts

-

Moving Work-in-progress (WIP)

-

Lineside Delivery of Components

-

Powering the Production Line

Towing Mother and Daughter Carts

Tow tugs are often used alongside mother and daughter trolley configurations. Mother trolleys tow one or more daughter trolleys, creating a train system that improves operational efficiency. Electric tow tugs, as the name suggests, are then utilised to tow the train system.

Utilising material handling tugs alongside mother and daughter trolley systems enables manufacturers to achieve greater throughput, improved ergonomics, and enhanced efficiency across their operations.

Moving Work-in-progress (WIP)

Alongside towing trains of carts, material handling tugs can be implemented to move large and heavy loads like sub-assemblies and work-in-progress. Manufacturers trust powered tugs to mobilise high-value loads and deliver unrivalled precision and manoeuvrability. Example movements include:

- In the automotive industry this is often loads such as chassis, body-in-whites (BiW) or powertrain assemblies

- Within aerospace manufacturing, this often includes the movement of sensitive loads like aerostructures, composites and wings

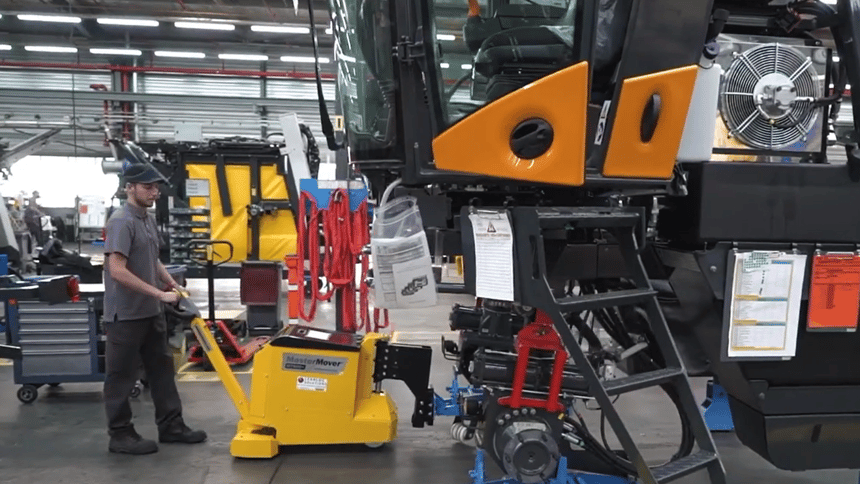

- Heavy plant equipment manufacturers utilise electric tugs to mobilise loads such as chassis, sub-assemblies and booms

Lineside Delivery of Components

Across industrial manufacturing sectors such as automotive manufacturing, heavy plant assembly and aerospace, the timely delivery of components to the production bays and the assembly line is integral to maintaining throughput and reducing downtime. With no operator licence required, powered tugs allow a single operator to move components just-in-time, offering a more efficient solution for intralogistics and internal material flow.

Powering the Production Line

As well as supporting processes like those outlined above, electric tuggers can also be used to power the production line. As a modular and more flexible solution, they offer a scalable alternative to fixed chain driven production lines or other traditional systems. Utilising material handling tugs to mobilise the production line enables manufacturers to benefit from greater flexibility, allowing them to scale up or down in line with output.

Explore our Range of Industrial Electric Tow Tugs

Our wide range of electric tugs and tows are designed using the same guiding principle – dependable performance, whether you’re moving 500kg or over 30,000kg.

Compact

Up to 6,000 kg

You need material handling solutions that improve safety and efficiency. Our electric tow tugs enable you to move loads in tight spaces.

Performance

Up to 70,000 kg

Moving heavy loads is what we do. Our performance range of electric tugs empowers you to move up to 70,000kg.

Automation

Up to 30,000 kg

Take advantage of fully autonomous load moving to move loads up to 30,000kg. Unlock greater efficiency and streamline processes.

The ultimate guide to material handling

Material handling equipment

Looking to understand material handling in a little more detail?

We’ve compiled some helpful resources to get you started.

Balancing Efficiency and Safety in Material Handling

Efficiency and safety are paramount considerations in material handling, especially when dealing with heavy loads within manufacturing environments. Material handling tugs play a crucial role in addressing these concerns by providing a combination of enhanced handling capabilities and safety features.

Safety as Standard

Ensuring the safe handling of heavy loads is a top priority in any manufacturing operation. Industrial tugs are designed with robust construction and powerful towing capabilities, allowing them to move the heaviest loads with ease. Our industrial electric tugs are equipped with impressive safety features such as adjustable speed settings, emergency stop functions, anti-crush systems and automatic braking, which help operators maintain control and prevent accidents when manoeuvring heavy loads through congested or tight spaces.

Incorporating motorised tugs into processes can significantly improve overall safety within manufacturing facilities. By reducing the need for the manual pushing and pulling of heavy trolleys, they minimise the risk of strain-related injuries.

Supercharging Intralogistics Efficiency

Streamlining production processes is another key benefit of utilising material handling tugs, particularly in the form of tugger trains – where a tug can move multiple loads at once. This approach not only optimises material flow but also improves efficiency and enables the just-in-time movement of parts, components and equipment. Alongside their ability to move multiple loads at once, material movers also free up staff to work on more valuable tasks by enabling a single operator to move loads with confidence.

Ready to Unlock Safer, More Efficient Operations?

Are you looking to improve safety and efficiency in your material handling processes? Contact us to discover how you could transform your processes to enhance efficiency and maximise workplace safety with electric material handling tugs.