Electric Tugger FAQs

Explore frequently asked questions about electric tuggers, tow tugs and pushers…

General

- A weight transfer system: A secure coupling system transfers an element of the load weight through the machine drive wheel to gain traction and mobilize heavy loads.

- Using the machine weight: The tow tug utilizes its' own weight to gain traction and enable the movement of heavy loads.

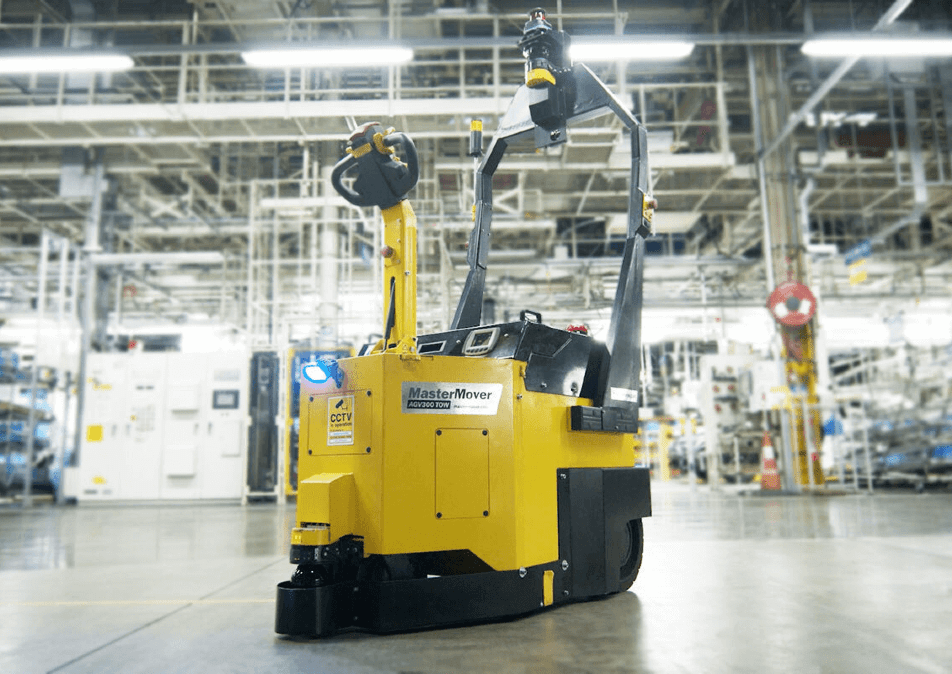

Electric tuggers are a type of battery-powered material handling equipment that allows a single pedestrian operator to move heavy loads on wheels without any physical effort.

They provide a safe and highly efficient way to maneuver heavy-wheeled loads in a controlled manner. MasterMover’s extensive range of tow tugs enables the safe movement of loads up to 154,000 lbs. with a single machine and even up to 793,000 lbs using multiple machines.

MasterMover boasts an extensive range of machines designed to improve the handling of heavy-wheeled loads.

The SmartMover range is the perfect manual handling solution for moving loads weighing up to 4,400 lbs. With a compact machine footprint and a range of secure coupling options, the SmartMover range is often used to mechanize the movement of loads previously handled manually – reducing the risk of injury.

For loads weighing up to 44,000 lbs., our MasterTug and MasterTow range delivers powerful performance and enables a single operator to easily move loads on castors or rails.

While all ranges can handle common floor conditions within industrial environments and outdoor use, our AllTerrain range is specifically designed to work in the most challenging of environments.

For the movement of trailers, our Trailer Moving System offers a compact trailer moving solution, enabling unladen trailers of 44,000 lbs. to be moved with complete confidence.

In addition to our range of standard pedestrian-operated electric tuggers, we offer a range of technology options for customers looking to further amplify electric tuggers' efficiency and safety benefits with future-proof technology. Many of our electric tuggers are available with remote control operation for improved visibility or as fully autonomous AGV solutions to maximize efficiency.

Whichever electric tug you select, you’ll benefit from improved safety and efficiency within your operations.

A full range of industries uses our electric tuggers to improve workplace safety and drive efficiency gains. From the movement of waste bins in facilities management to the movement of aero engines through maintenance – our tow tug solutions are relied on to deliver time and time again.

Many of our customers work within industrial manufacturing environments such as construction, mining and agricultural equipment, pharmaceutical manufacturing, energy, automotive and aerospace.

An electric tugger is a battery-powered machine that uses a series of motors to deliver the powerful movement of heavy-wheeled loads.

As with anything involving movement, traction is crucial to getting loads moving. Our electric tuggers can be divided into two main functional design categories based on how they generate traction:

Electric tuggers offer a safer way to move heavy-wheeled loads that were previously carried out manually or by using traditional material handling equipment such as forklift trucks or tow tractors.

Our electric tuggers boast an impressive range of standard safety features to ensure that the operator is always in control. Features include an emergency stop button, an anti-crush system that activates immediately if the user’s body comes into contact with it and a sensor that automatically cuts off the power when the tiller arm returns to vertical – preventing accidental operation.

Machines also feature a warning horn and a self-adjusting castor guard that prevents the risk of foot trapping.

Further safety options are available such as a two-speed selector switch to suit your operating environment and a flashing safety light and motion bleeper.

Can electric tuggers stop a load? Your electric tugger is physically connected to your load so when the tugger stops, the load stops.

Each machine has several braking mechanisms that ensure it is safe to use in every eventuality. The operator can simply release the controls, and the load will come to a halt.

An emergency stop button can be manually pressed if needed; otherwise, it is automatically activated when the tiller arm is returned to its vertical home position (i.e. you cannot use the machine with the tiller arm in a vertical position).

No, you do not need a license to use an electric tugger. This is one of the many reasons industrial manufacturers are increasingly opting for electric tuggers to create an environment without forklifts.

With an electric tugger, you no longer need to wait for the availability of a licensed forklift truck driver to move a load.

Likewise, with no operator license required, you can seamlessly integrate electric tugs into your processes, whether that’s to eliminate manual handling or reduce reliance on traditional handling equipment.

Yes, training is available on all machines to ensure your operators use electric tuggers safely and maximize usage rates.

Yes, MasterMover electric tuggers are available worldwide and are supported by our network of dealers on every continent.

Products manufactured and sold in Europe are required by law to comply with CE standards.

Outside of the EU, CE marking does not hold any authority, although many countries respect the strict conditions a product must meet to be CE marked, thus confirming the product is safe to use.

All MasterMover products are CE marked so they meet EU health, safety and environmental requirements.

Your company can incorporate a MasterMover tug safe in the knowledge that it conforms to all appropriate legislation.

Electric tow tugs can be used to push and pull heavy loads on rails. Our electric tuggers are used to deliver the safe, controlled movement of heavy loads such as rail bogies and sub-assemblies on rails.

Yes. We understand that every application is different and sometimes, standard material handling equipment might not be suitable for your requirements. Our dedicated in-house Custom Engineering team is on hand to provide custom solutions for your unique requirements.

Pricing

MasterMover operates globally through direct relationships and a network of sales partners and we have demo units available across a range of regions. Please contact us to discuss arranging a demonstration.

We also offer a range of standardized delivery options. Whether you need your electric tugger to be delivered straight to your site, to a chosen port, or on an FCA basis where your nominated forwarder can collect straight from our warehouse, we can provide the right option for you.

With an expansive range of global customers, our electric tuggers can be purchased in USD, GBP, or EUR depending on your location.

Training is available on all machines to ensure your operators use electric tuggers safely and maximize usage rates. We also offer refresher training to retain competency levels and ensure safe operation.

Regular servicing is the key to safeguarding your electric tugger’s performance. We offer a range of planned preventative maintenance programs designed to ensure that your electric tugger is always safe and reliable

Where an electric tugger is an integral part of your operations, we recommend purchasing a service and maintenance plan to optimize performance and ensure equipment longevity.

We quote our electric tugger solutions with a relevant battery, charger, coupling system, packaging, and delivery – everything you need to get started.

Additional bolt-on options are available such as training, maintenance packages and installation if required.

Stainless steel is more expensive than mild steel alternatives due to the addition of a range of other alloying elements. Different grades of stainless steel are available, influencing the price and preparation involved.

Our stainless steel electric tuggers are used in highly controlled environments such as food manufacturing and biopharmaceuticals, so we use high-grade 316 stainless steel.

Technical & Machine

- Load weight

- Slopes

- Floor (Material, type, and condition)

- Castor wheels (Material, diameter, quantity, orientation, condition)

- Load weight and route

- Run speed

- Battery specification/size

- Environmental conditions such as temperature

Rolling resistance is the force resisting the motion when an object rolls on a surface and is an important consideration when it comes to electric tuggers.

Rolling resistance can be affected by a number of variables including:

All of these variables play a role in determining the rolling resistance of an application and in turn, the total force needed to move a load from an electric tugger.

For example, steel castors running on rails have a very low rolling resistance which means less force is required to start the load moving and stop it.

Rolling resistance plays a vital role in determining an electric tugerg or tow solution, so it must be considered.

The higher the rolling resistance, the more power is needed from an electric tugger to start the load moving.

We use information on your environment, movement and castors to calculate the estimated rolling resistance and in turn, the force required to move and slow down your load. This enables us to specify a suitably powered electric tugger or tow to mobilize your load.

A coupling is a device that allows a connection between a load and an electric tugger. Each machine has an array of standard coupling options available, and we’ll ensure the correct one is specified for your application.

For applications where a standard solution isn’t suitable, we can design custom solutions.

Different machine ranges use different coupling systems and your MasterMover representative will ensure that any coupling is right for your requirements. However, here is a basic explanation of the common coupling types and how they connect to your load:

Clamp – Our SmartMover range uses a clamp-style coupling that clamps onto the frame of your cart to connect directly to loads. Where a direct connection can’t be made, adaptors can be bolted onto your carts.

CombiCoupling – Available on our MasterTug range, this utilizes a male coupling mounted on the tug and a female coupling that is fitted onto your cart. The male and female connect using hydraulics to create a secure connection to your load.

Pin & Ball hitches – Used across our MasterTow range, pin couplings enable the quick and easy connection to loads fitted with drawbars. Ball hitches are also available.

Custom Couplings – Where a standard coupling isn’t suitable, we can work with you to create custom couplings. Whether that is to connect to an existing system on your cart or a solution to work with various different trolley designs, our team can advise on the right solution.

An electric tugger is a machine designed to push and pull in an equal measure using weight transfer to gain traction. An electric tow is a self-weighted machine predominantly designed to pull (or tow) loads.

We’ll use technical information on your application and understand your movement requirements to specify the right solution for you.

Electric tuggers are designed to move loads on wheels or rails.

For maximum maneuverability and control, it’s recommended that your cart should have 2 x swivel castors at the front and 2 x fixed (or directionally locked at straight) castors at the rear.

All-swivel castor loads can be mobilized by using our MasterHandler range, which provides a fixed point to help stabilise a load. Alternatively large, awkward loads can be mobilized using a two-tugger system that enables operators to work in tangent to pivot a load on its axis, resulting in maximum maneuverability.

Like any battery, the battery life of an electric tugger or electric tow is determined by usage, specification, and environmental factors. Battery life can be influenced by variables such as:

Yes. Lithium batteries are available on many models within our range for applications where charging can only take place in short, sharp bursts.

Lithium batteries allow operators to charge the batteries for short periods (known as opportunity charging) and are a perfect solution for high-intensity operations.

Recharge times for standard AGM batteries are typically between 6-7 hours, with these timings based on recharging from 30% to 100% on standard batteries.

Alongside the benefit of opportunity charging, lithium batteries have significantly faster recharge times than lead-acid batteries, with recharge times often between 1-4hrs.

Technology

- Line follow - This technology ensures an electric tugger follows a line on the floor, delivering highly accurate repeated movement between points. This is especially useful when moving loads through tight spaces, or when accurate movement is required. Scanners monitor for hazards and risks, bringing the tugger or tow to a stop if the need arises. The AGV can read barcodes or other prompts, to stop under certain circumstances, or slow down or speed up in different locations.

- Natural navigation - Our full AGV solution utilizes the latest in navigation and safety sensor technology to deliver electric tugs that interact with their environment, traveling safely and efficiently between destinations.

Yes, we offer an extensive range of autonomous electric tuggers, designed to optimize the movements of heavy loads weighing up to 154,000 lbs.

Whether you need an out-of-the-box solution to deliver continuous, repeatable movements using Line Follow navigation, or a more intuitive system that utilizes natural navigation to engage with its’ environment, our AGV systems can be customized to your needs.

Learn more about our AGV Systems

Eliminating the need for an operator, AGVs drive maximum efficiency and automate the movement of loads to boost resource utilization and safety. With predefined movements, AGVs deliver the accurate movement of loads every time – making them ideal for use in tight spaces.

We offer two forms of AGV navigational technology:

Safety sensors detect obstacles and risks, slowing or stopping movement, for example reducing speed when the floor is wet and/or where visibility is impacted.

Navigation technology ensures the machine travels between destinations, interacting with your environment as required to take account or ideal routes, other machines, and operational factors.

Yes, many of our electric tuggers can be operated using a remote control. This enables operators to maneuver into the best vantage point, delivering increased visibility and reducing the risk of collisions.

Available on our PowerSteered range, innovative MultiLink technology allows multiple electric tuggers to work in synchronization under the control of a single operator.

This allows an unrivaled range of movement, maneuverability, and control – ideally suited to move awkward loads. Using MultiLink also allows you to move heavier loads by using the combined weight-moving performance of individual electric tuggers.

Application & Environmental

We follow a tried-and-tested approach to specifying an electric tugger for your application where we collect information on the maximum load weight, environment and route you need your electric tugger to work on. From there, our engineers will calculate the most suitable electric tugger solution for your needs.

Specifying an electric tugger that is fit for purpose and will deliver tangible safety and efficiency benefits right out of the box is critical to us. An array of factors influences the specification, performance and price of an electric tugger and we need to understand them to ensure any solution is right for your application.

Collecting information and conducting a full assessment of your application prevents any issues in installation or performance.

Yes, all MasterMover machines will work on slopes. The maximum angle our tuggers are capable of clearing, on average, is 8°.

It is more important to remember that for every degree of slope involved, the maximum load capacity of the machine is reduced, just as pushing a car on the level requires less force than on a slope.

Therefore, if the weight of the load is already close to the maximum capacity of the machine a more powerful tugger may be needed to move the load on a slope.

To guarantee safety, traction and the control needed on an incline you should always PUSH the load UP a slope and PULL the load DOWN a slope with an electric tugger.

PUSH up/ PULL down, ensuring the user is always in front of the load.

Our electric tuggers will work on a range of floor surfaces. Electric tuggers are often required to work on common industrial floor materials such as painted concrete, tarmac, epoxy and rough concrete.

Similar to inclines, the maximum load capacity of a machine is affected by the floor surface. For example, it requires a greater force to move a load on a tarmac floor than it does on a smooth concrete floor.

All of our machines can be used outside and/or in wet conditions, with some electric tuggers designed specifically to be used in those conditions. The All Terrain range of electric tuggers is particularly suitable for rough or challenging floor surfaces.

Operating outside normally means the machines have to work on tarmac or uneven concrete and deal with slopes, all of which inevitably affect the maximum load weight of a particular machine.

Our Stainless Steel Range includes machines with higher Ingress Protection (IP) ratings, making them ideal for use in food processing, pharmaceutical and chemical applications.

When we’re assessing which electric tugger best suits your application, we work on a worst-case scenario to ensure any electric tugger specified is up to the job.

Yes, for safe load moving in potentially hazardous working conditions, MasterMover can convert our equipment to meet ATEX and IECEx standards.

Machines can be converted to meet zones 1 and 2 (gaseous explosive environments) and zones 21 and 22 (powder or dust explosive environments).

Yes, our Stainless Steel range of electric tuggers is widely used in highly controlled environments such as biopharmaceutical manufacturing and food processing.

Our tugs are made with 316-grade stainless steel, facilitating easy cleaning and use in sterile environments.

Custom solutions

For applications where a standard solution isn’t the right fit, we have a dedicated engineering team on hand to create custom solutions. With 25 years of industry experience in providing customized solutions, you’re in safe hands with MasterMover.

Yes, we offer custom couplings. Where a standard solution isn’t suitable, we will work with you to assess if a customized coupling can be designed.

Situations where this often arises are where you may have a high quantity of carts that can’t be modified, no obvious connection point, or where there are space restraints on your cart.

Yes, if you need an electric tugger in a specific color simply provide us with the required RAL code and we’ll make sure your tugger is painted to your requirements.

Service & Maintenance

Our electric tuggers come with a 12-month warranty as standard. The tugger chassis and metalwork are also covered by a five-year structural warranty.

We offer an extended major component warranty on all our machines for up to five years – this means that you only pay for consumables and damage.

Our extended warranty includes comprehensive cover against sudden mechanical or electrical failure of all factory-fitted components on your electric tugger.

We’ll be happy to support you in logging a warranty claim. To do so, please contact us or call 980-263-2210.

Service intervals for electric tuggers depend largely on how often they are used. We offer two service packages that include 2 services per year for low to medium usage and 4 for high usage.

To ensure your machine is always in good working order, we suggest you pick the right frequency of service for your usage rates.

Contact the MasterMover parts team at parts@mastermover.com or call 980-263-2210

Yes, our expert engineers are trained to service a wide range of manual handling equipment using the latest techniques and diagnostic tools, meaning that you can consolidate all your servicing under one provider.

Some of the other machines we cover include ride-on tuggers, pallet trucks, pallet stackers, floor scrubbers, floor sweepers, robot wrappers, AGV machines and more.

Can’t find the answer you’re looking for?

Ask our experts

Automated Guided Vehicles

Maximize production efficiency and accuracy with an AGV

Our AGVs deliver the predefined, controlled movement of loads – without the need for an operator.

You can maximize efficiency and guarantee the safe and precise movement of high-value loads every time with our AGV systems.