Types of Automated Guided Vehicles

Automated Guided Vehicles

What are the most common types of Automated Guided Vehicles (AGVs)? In this blog, we take an in-depth look at the different types of AGV, typical applications and the benefits.

Thank you for your request to download the MasterMover 'Guide to Autonomous Guided Vehicles'.

We'll also send you an email shortly with your download link included for safekeeping.

If you do not receive the email, please let us know at salesteamusa@mastermover.com.

Thank you for your request for an AGV System Consultation!

One of our representatives will be in touch with you shortly to discuss your request in more detail.

Exploring the Different Types of Automated Guided Vehicle Systems

Automated Guided Vehicles (AGVs) have revolutionized industries across the globe, offering a cost-effective and efficient solution to labor-intensive material handling and inefficient internal transportation.

So, whether you're working in a manufacturing facility looking to optimize your production line, a warehouse in need of efficient material flow, or are a supply chain manager seeking to enhance the overall efficiency of your operations, this article will provide you with a deep understanding of the different types of automatic guided vehicles and how they can help drive operational efficiency. In this blog, we cover the different types of AGV, including:

AGV Forklifts

Forklift AGV systems are autonomous vehicles that lift, move, and stack heavy loads without human intervention. Automated forklift trucks are widely used in various applications and industries. In warehouses and logistics distribution centers, AGV forklifts are used to optimize material flow and space utilization by efficiently moving palletized goods. Automated forklifts have advanced technology and use navigation systems like laser or vision-guided technology to maneuver accurately along routes.

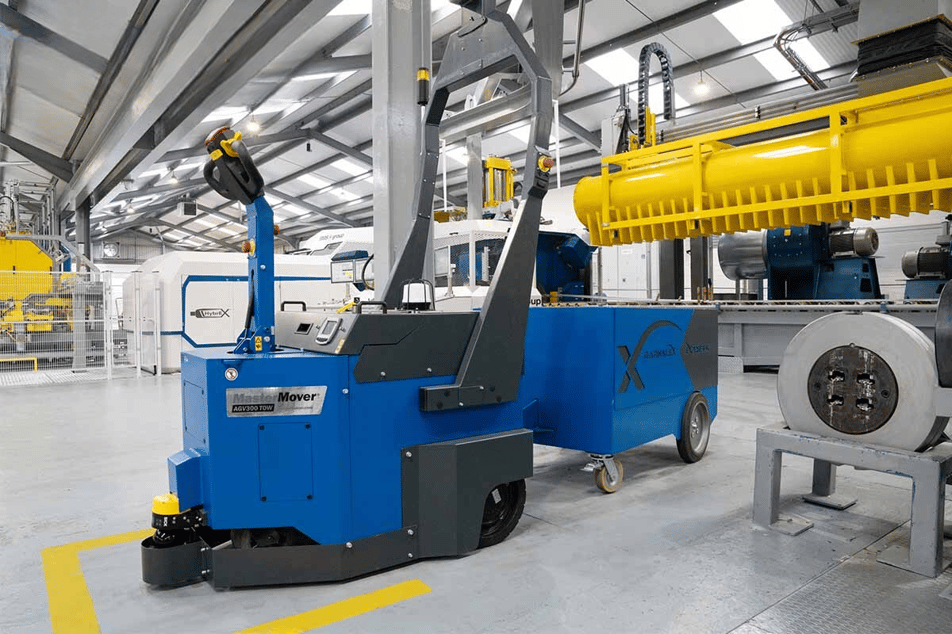

Towing AGVs & Tugger AGV Systems

A automated towing AGV system excels at moving heavy-wheeled loads, navigating tight spaces and improving operational efficiency. They efficiently transport multiple carts at a time, creating an automated tugger train, saving time and optimizing space. Automatic towing and tugger AGV systems are ideal for assembly lines, ensuring a continuous flow of materials, enhancing productivity and streamlining operations.

The Benefits of Towing AGVs

Automated towing vehicles offer a range of benefits across industries. Towing AGVs and tugger AGV systems eliminate the need for manual labor in low-value-adding tasks like towing applications of moving goods from A to B – freeing up staff to work on more productive tasks.

Automated towing systems:

- Can tow a heavy load

- Are able to tow multiple loads at once

- Are best suited to repetitive movements

- Improve operational efficiency

Thank you for your request to download the MasterMover 'Guide to Autonomous Guided Vehicles'.

We'll also send you an email shortly with your download link included for safekeeping.

If you do not receive the email, please let us know at salesteamusa@mastermover.com.

-

Repeatability

Precise movements, every time. By their nature, AGVs are a great fit for delivering repeatable movements.

-

Better utilization of people

AGV solutions make movement of equipment and materials more efficient and allow your people to focus on value-adding tasks. -

Eliminate human error

Towing AGVs take control away from a human operator. Safety sensors ensure a programmed response to any detected risk, stopping movement until a hazard has been cleared or moved away.

-

Improve operational efficiency

AGVs drive operational efficiency by reducing wasted movement and freeing up staff to work on more productive tasks.

Who Uses Towing AGVs?

Industries like industrial manufacturing, automotive and logistics distribution centres rely on automated towing vehicles and tugger AGV systems for seamless material handling. They contribute to just-in-time delivery, efficient supply chain management, and improved material flow. Whether it's moving raw materials to the assembly line or transporting finished goods, this type of AGV system plays a crucial role in enhancing operational efficiency and safety.

AGV Systems – Case Study

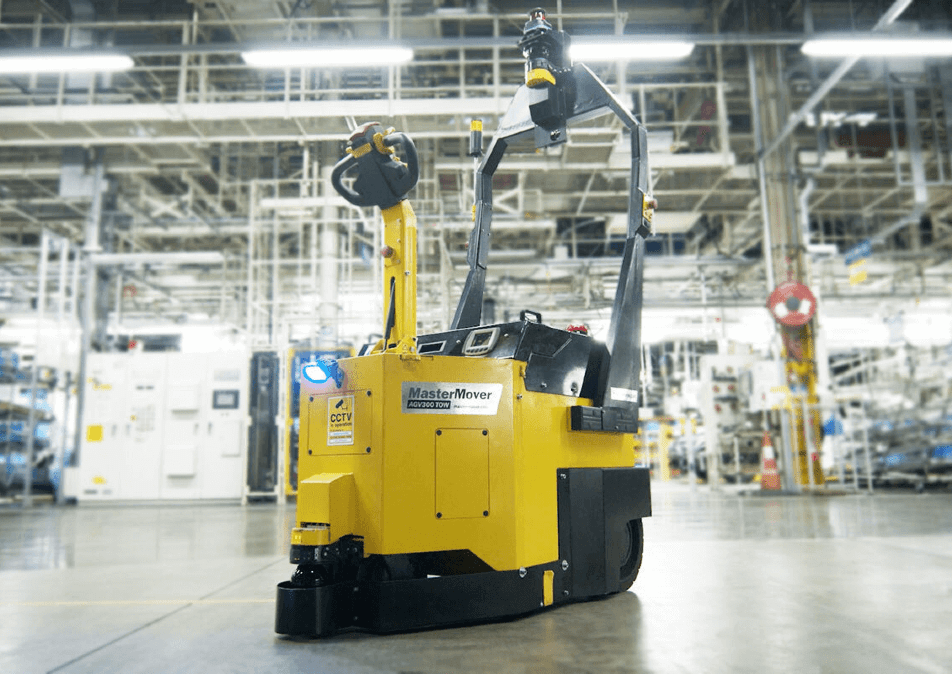

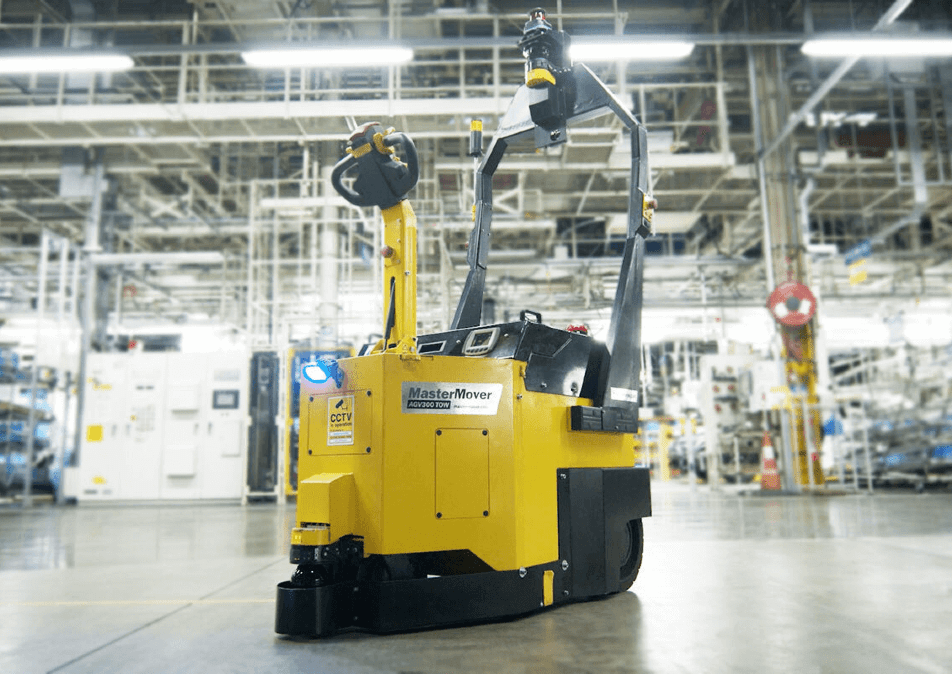

Toyota Accelerates Efficiency with a Towing AGV System

A world leader in its field, the automotive manufacturer has achieved return on investment and improved operational efficiency when moving parts to the production line with a MasterMover AGV…

Unit Load AGVs & Automated Unit Load Carriers

Unit load AGVs and load carriers are one of the most common types of Automatic Guided Vehicle systems. They are designed to carry and transport heavy loads and unitized loads throughout warehouses and production facilities.

The design of an automated load carrier allows loads to be loaded onto the unit and then transported along a defined route. One of the key benefits burden carrier AGV systems and automated load carriers deliver is their ability to streamline operations and optimize material flow.

By automating the load transportation process, businesses can eliminate the need for manual labor, reducing the risk of human error and increasing productivity. This type of AGV is particularly useful in industries that require frequent movement of heavy loads, such as warehouses and distribution center's.

The ultimate guide to AGV electric tuggers

Automated Guided Vehicles (AGV)

Looking to understand Automated Guided Vehicles in a little more detail?

We’ve compiled some helpful resources to get you started, covering everything you need to know.

Automated Pallet Trucks

AGV pallet trucks are specifically designed to handle pallets and move palletized loads. With advanced technology and precise navigation systems, automated pallet trucks can efficiently transport pallets from one location to another, minimizing manual labor and maximizing efficiency.

Pallet truck AGVs can operate autonomously, performing repetitive tasks without the need for human intervention, allowing workers to focus on higher-value activities. This makes them ideal for industries that require frequent pallet movements, such as e-commerce fulfilment center's, logistics depots, and manufacturing facilities.

In terms of functionality, Automated Pallet Trucks are equipped with specialized forks or clamps that securely grip and transport pallets.

Automated Guided Carts (AGCs)

Automated Guided Carts (AGCs) are designed to transport smaller loads, such as bins, totes, or boxes, within industrial facilities. AGCs are highly configurable and can be adapted to various applications, making them a valuable asset in diverse industries, including industrial manufacturing, retail and automotive industries.

An automated guided cart can navigate through congested environments, such as production lines or assembly areas, with ease, allowing for efficient and timely material transport. Unlike typical AGVs systems that are available with more advanced navigational technology, Automated Guided Carts typically navigate through line follow navigation.

Your Questions, Answered - FAQs

As with any equipment, it’s important to assess the different types of automated guided vehicles alongside your operations, your objectives, and future requirements. For example, if you business aims to remove forklift traffic from internal processes in the future, you may want to reconsider if an AGV forklift is the right option and assess if AGV tugger systems may be a more future-proof solution.

When buying an AGV, there are a number of factors to consider - including your operations, desired benefits and movement needs. Dive into our Buying Guide below!

AGV Efficiency: Automated Guided Vehicles enable businesses across industrial manufacturing and logistics to drive operational efficiency, increase resource utilization and reduce non-value-adding tasks in their material handling processes.

With the rise in industrial automation, many businesses look to automatic guided vehicles to streamline the movement of heavy materials and loads, eliminating the need for human involvement.

Automated Guided Vehicles are available with a range of different navigation and guidance system options. Simple AGV solutions utilize line-follow systems to follow a predefined route on the floor. For more complex and advanced requirements, a navigation system known as ‘natural navigation’ is available. Using a natural navigation system and sensor technology, an AGV maps its surroundings during installation, enabling it to navigate along its route seamlessly.

AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) are both types of mobile robots used for automation in various industries. The main difference between AGVs and AMRs lies in their autonomy and flexibility. AGVs typically follow fixed paths or routes, either through environment mapping or magnetic strips on the floor for line-follow systems.

Alongside the rapid innovation and advancement of Automated Guided Vehicles, the market for other automation solutions is expanding. Other industrial automation solutions including automated storage and retrieval systems, conveyor systems, warehouse automation and warehouse management systems are rapidly advancing.

Automated Guided Vehicles

Maximize production efficiency and accuracy with an AGV

Our AGVs deliver the predefined, controlled movement of loads – without the need for an operator.

You can maximize efficiency and guarantee the safe and precise movement of high-value loads every time with our AGV systems.

Ready to Implement Your Towing AGV System?

If you’re ready to unlock the power of automation and drive operational efficiency, our Automated Guided Vehicles are the perfect fit.

Fill in your details, and one of our automation experts will reach out to discuss your application.