Moving Heavy Loads: Manual Handling vs. Electric Tugs

Manual Handling

In this guide, we’ll walk you through the challenges of manual handling and when electric tugs might be a better option than relying on risky manual grunt work.

More Than Just "Putting Your Back Into It"

The age-old adage of ‘put your back into it’ is a phrase that most of us are familiar with in one way or another. But when it comes to moving heavy-wheeled loads like trolleys, carts, or waste bins, it can have serious consequences.

What is Manual Handling?

Manual handling involves the physical movement of materials by human workers. This can include lifting, carrying, pushing, and pulling tasks.

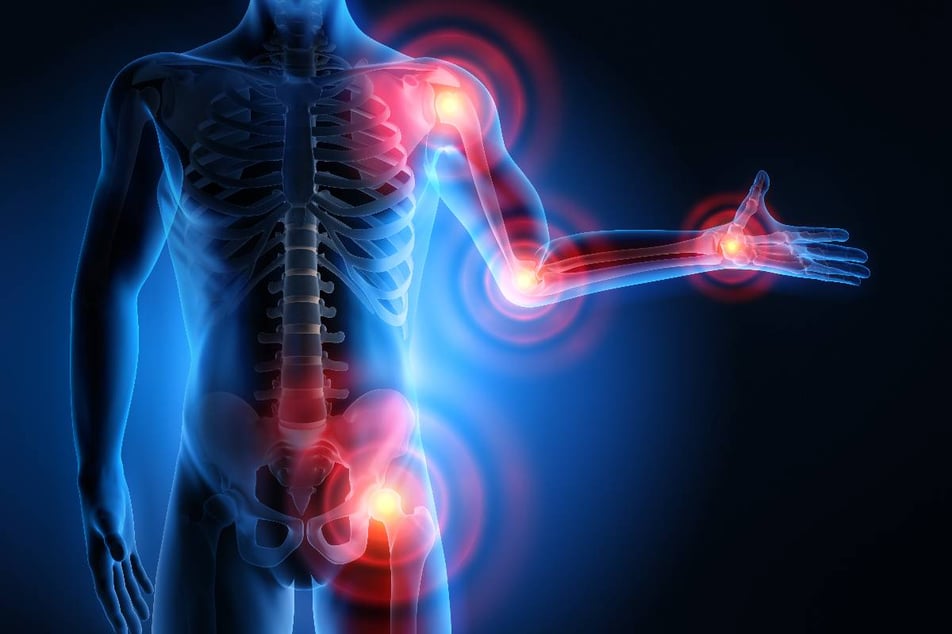

What are the Issues with Manual Handling?

For the infrequent movement of light loads over short distances, manual handling is perfectly fine – assuming that staff have had the correct training to ensure proper posture and safe handling processes. Where manual handling poses more of a risk is when loads exceed an employee’s ability, movements are over longer distances, positioning is awkward, or where the movement of loads is repetitive.

For example, carrying a 5kg component from one production bay to another every now and again is unlikely to result in a manual handling injury. However, manually moving 450kg fully loaded roll cages across a fulfilment centre, day-in and day-out is likely to require multiple members of staff and present a significant risk of injuries and strains.

What are Electric Tuggers and When Would I Need One?

Electric tugs are battery-powered vehicles designed to move heavy-wheeled loads with ease. Using a pedestrian electric tug dramatically reduces the risk of sustaining back injuries or strains by replacing muscle power with an electric motor.

They come equipped with advanced features such as ergonomic controls, powerful motors, and safety systems. Commonly used in manufacturing, warehousing, healthcare, and facilities management, tugs are celebrated for their efficiency and safety benefits.

Manual Handling Risks: 29% of Workplace Injuries Due to Overexertion

Travelers Injury Impact Report

Common Myths About Manual Handling

-

“But manual handling is quicker”

-

“We can’t afford to invest in equipment, manual handling is much cheaper”

“But manual handling is quicker”

The belief that manual handling is quicker is a myth that overlooks significant factors like the risk of injury, downtime, and labour requirements. While it might seem faster initially, manual handling increases the risk of musculoskeletal disorders and injuries, which can lead to extended downtime for workers and costly compensation claims for businesses. It’s important to remember that the heavier the load, the more force is needed to move it. So, moving heavier loads manually often requires more people, reducing overall efficiency and increasing labour costs.

“We can’t afford to invest in equipment, manual handling is much cheaper”

The idea that manual handling is cheaper than investing in equipment is a misconception that fails to account for the hidden costs of injuries, productivity losses, and higher labour expenses. Manual handling increases the likelihood of workplace injuries, leading to medical expenses, compensation claims, and staff absence – all of which have an associated cost.

The Benefits of Pedestrian Electric Tugs

You need material handling solutions that enhance processes, not hinder them. Our electric tugs offer a flexible solution enabling the efficient and safe movement of heavy loads when compared to manual handling.

-

Create leaner processes

Internal transportation is a non-value-adding process that takes staff away from more fulfilling work. License-free electric tugs streamline the movement of loads to create leaner processes.

-

Maximise staff safety

By eliminating manual handling and reducing the risk of injury - pedestrian electric tugs help improve workplace safety.

-

Improved productivity

Where loads might have required multiple members of staff to move, with a tug a single operator can move the heaviest loads - improving staff productivity.

Advantages of Powered Tuggers vs Manual Handling

Increased Efficiency and Productivity

Electric tugs can transport materials much faster than manual methods, leading to higher throughput and reduced handling times. By using an electric tug to take the strain, a single operator can move the heaviest loads simply through thumb power. A distinguished manufacturer of retail refrigeration, Arneg recently used SmartMover tugs to take the movement of heavy carts from a six-person movement by hand to a one-person job in our latest case study.

Enhanced Safety

Electric tugs significantly reduce the risk of injuries compared to manual handling. Their ergonomic design minimises physical strain on workers, preventing common musculoskeletal disorders and injuries. A leading workers' compensation insurance carrier analysed more than 1.5 million workers' compensation claims between 2015 and 2019. The findings highlight just how risky it is to keep staff moving heavy loads by hand.

The report found that the three most common causes of all injuries were:

- 29% overexertion

- 23% slips, trips and falls

- 13% struck by an object

Delving further into the report, the most common causes of workplace injuries found were:

- 38% were strains and sprains

- 35% were fractures, dislocations, contusions or inflammation

- ¼ of all claims analyzed involved the lower back and shoulders

The Health & Safety Executive (HSE) found that 477,000 workers are suffering from work-related musculoskeletal disorder (new or long-standing) - of which manual handling is a key contributor.

They also found that musculoskeletal disorders account for 24% of all days lost due to work-related ill health and work-related illness.

Cost Savings

A leading compensation claims company found that claims for severe workplace back injuries can be as much as £160,000.

Though the initial investment of a powered tug is higher, the long-term savings are substantial. Reduced injury-related costs, lower staff absence, and improved productivity contribute to the overall cost efficiency of switching to a safer solution.

Your Guide to Tackling Manual Handling

Manual Handling

Explore our comprehensive manual handling resource hub—expertly curated materials designed to enhance workplace safety. Elevate your knowledge and empower your team to prevent injuries, making your workplace safer and more efficient.

Electric Tugs vs. Manual Handling - ROI & Cost

Initial Investment

Manual handling aids like tugs require an initial purchase, whereas manual handling has virtually no upfront costs – aside from the obvious associated labour costs and the secondary costs we’ve already covered.

Operational Costs

Electric tugs have lower long-term operational costs due to reduced injury-related expenses and higher efficiency. Manual handling, while initially cheaper, can lead to higher cumulative costs over time.

Compensation and Injury Costs

Injuries from manual handling can result in significant healthcare expenses and compensation claims. Pedestrian tugs help mitigate these costs by enhancing workplace safety and reducing the risk of injury.

Time-Saving Aspects

Powered tugs streamline material movement, significantly reducing handling times compared to manual methods.

Impact on Workforce Productivity

Taking the strain out of moving heavy loads and enabling a single operator to move the heaviest loads, tugs lead to higher overall productivity.

By understanding the benefits of electric tugs and the hidden costs of manual handling, businesses can make informed decisions that enhance safety, efficiency, and cost-effectiveness in their operations.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.