Continue reading

Continue reading

Chemical Material Handling Equipment

Thank you for submitting your demo request.

A member of the team will be in touch shortly.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Typical electric tug applications

Electric tugs are used by leading chemical manufacturers to improve safety and efficiency when moving loads such as:- Mixing vessels

- Powder containers

- Hoppers

- Storage bins and totes

- Waste containers

From multinational painting and powder coating manufacturers to resins and solvents, our electric tugs help chemical manufacturers eliminate manual handling and boost productivity.

Electric tug benefits for the chemical industry

Eliminate manual handling

Taking the strain, electric tugs remove the risks associated with manual handling.

Maximising production efficiency

Delivering speed and simplicity, electric tugs help drive production efficiency.

Safe and controlled movement

Featuring secure coupling systems, our electric tugs ensure the safe and controlled movement of wheeled loads.

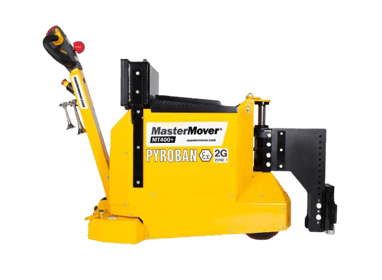

ATEX-rated equipment

Our ATEX-rated tugs ensure a safe, spark-free operation – ideal for environments with using Volatile Organic Compounds (VOCs).

Popular electric tugs for chemical manufacturing

Our electric tugs in chemical manufacturing settings

.jpg?length=1200&name=chemical-section-atex%20(2).jpg)

Case study

Coatings manufacturer trusts ATEX-rated electric tugs

A company in Poland that manufactures protective coatings uses our MasterTug range, modified to meet ATEX Zone 2 standards, to enhance safety while moving vessels within a potentially explosive environment containing VOCs.

Trusted by chemical giants

Chemical manufacturers from across the globe trust our electric tugs to maximise their shopfloor safety and efficiency.

MasterMover are easy to work with and all products performed as advertised. Moved our heavy products with ease!

Parker MacciantiMechanical Engineer

Why choose MasterMover?

- The world's leading manufacturer of electric tugs for over 25 years

- Over 40+ electric tugs to choose from

- Unrivalled range of technology and control options available

- Trusted by leading chemical manufacturers

- In-house custom engineering capabilities

- Winner of the King's Award for Innovation 2023 & Queen's Award for International Trade 2021

- Global sales and support

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Your Questions, Answered - FAQs

Yes, all of our electric tugs can be converted to meet ATEX standards. Our electric tugs can be converted to operate in zones 1 and 2 (gaseous explosive environments) and zones 21 and 22 (powder or dust explosive environments) to meet ATEX and IECEx standards.

Working with best-in-class explosion-proofing providers, MasterMover ATEX electric tow tugs can safely work in hazardous environments, allowing you to maximise workplace safety and efficiency.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving.

Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

A range of coupling options are available across the range that maximise performance, security and safety.

Custom coupling solutions can also be designed for unique applications.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

ATEX Electric Tugs Provide Safety and Efficiency North Sea