New MasterHandler

Compact power, zero drift

Adjustable and powerful, the next-generation MasterHandler range makes it easy to move loads with four-swivel and mixed-swivel setups in the tightest spaces.

Thank you for submitting your price request.

A member of the team will be in touch shortly.

.png?width=952&height=674&name=New%20MasterHandler%20Hero%20(3).png)

A classic, remastered

Big capacity, small footprint

The reimagined MasterHandler is our most compact, configurable electric tugger for difficult-to-control loads with swivel caster setups. A stabilizing leg slides under the load to eliminate drift, so that a single operator can easily and precisely move loads up to 13,000 lbs.

Control wheeled loads in tight spaces

Compact power in tight spaces

Stabilizing leg prevents drift

Adaptable for changing setups

Easy-swap batteries for 24/7 operation

New Electric Steer options

Advanced control upgrades

Upgrade your MasterHandler to the Electric Steer model to unlock all-new advanced control options. From remote control to innovative multi-machine synchronization as well as automation, for even more precision and visibility when moving long or heavy loads.

New MasterHandler models

Innovative engineering brings the power and precision of big machines in a compact electric tugger solution. The updated MasterHandler range eliminates drift on loads with four-swivel and mixed-caster setups, while the upgraded Electric Steer models offer various technology options for even more control.

MH400+

Up to 8,800 lbs.

MH400+

Up to 8,800 lbs.

Adaptable design

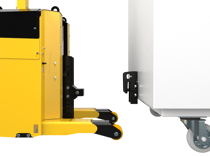

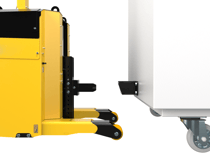

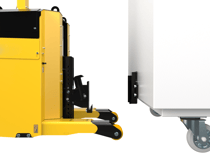

How it works

A modular leg sits beneath your wheeled load to create a control point and eliminate caster drift. A secure hydraulic connection and compact design positions the MasterHandler close to your load, giving maximum control in awkward spaces.

For even more precision, upgrade to the Electric Steer models for assisted steering, advanced control options, remote operation for full visibility, and line-follow technology for repeatable accuracy.

MasterHandler in action

/Images/MH400%201.jpg?width=2000&height=1500&name=MH400%201.jpg)

Safety & machine upgrades

Re-worked to combine the power of our larger machines with the compact precision of our smaller tuggers, the new MasterHandler range can be configured with different options to best suit your requirements.

Flexi Pin coupling

For superior slope performance and traction, even when machine and load aren't level.

Box coupling

Creates a secure connection, perfect for tackling rough surfaces and slopes.

Combi coupling

A secure connection for optimizing performance and maneuverability.

Custom couplings

Need something else? We can design couplings to suit your application.

Easy-swap batteries

Interchangeable batteries keep workstreams flowing.

Battery protection system

Maximize your battery service life by preventing damage.

External chargers

Guarantees fast, optimized charging for fixed locations.

Internal chargers

Onboard chargers provide flexible charging when you need it.

Two speed selector switch

Adjustable speed settings at your fingertips.

Safety light beeper

Maximize safety when moving loads through congested areas.

Emergency stop

Allows you to immediately stop the machine.

Anti-crush button

Protect operators and maximize operator safety when moving loads.

Warning horn

Perfect for congested areas, alert pedestrians when moving loads.

Automatic cut-off

Prevent accidental operation of the machine.

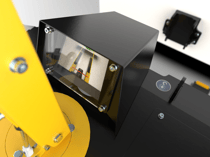

Front-facing camera

Even more visibility to maximize safety and precision when moving loads.

Pedestrian

Available on all MasterHandler models, effortless power steering for smooth operations.

Remote control

Optimal visibility for easy positioning with simple controls.

TillerLink

Combine the power of two pedestrian machines to boost maneuverability and precision.

MultiLink

Enable a single operator to control multiple MasterHandler tuggers with one remote.

Wireless AutoSteer

All the benefits of remote control to manage speed paired with line follow navigation for maximum control and safety.

Line follow AGV

Fully autonomous operation using line follow navigation for repeated moves.

Success story

Safe control for cereal manufacturer

A global cereal brand upgraded hopper handling with the MasterHandler MH400+, boosting safety and streamlining production flow while moving 800kg ingredient hoppers with precision.

Customers who trust the MasterHandler range

With the footprint of our compact machines and the power of our performance tuggers, the MasterHandler range is trusted by leading international brands to handle difficult-to-control loads.

Since we introduced MasterMover’s electric tuggers, we have never looked back! Their equipment revolutionized the way we handle heavy goods.

Akiva BrunnerBRNS Group Ltd

Why choose MasterMover?

- The world's leading manufacturer of electric tuggers for over 25 years

- Over 40+ electric tuggers to choose from; there's a model for every type of wheeled load

- Ideal for tight spaces

- In-house custom engineering capabilities

- Trusted by the biggest names in the business

- Winner of the King's Award for Innovation 2023 & Queen's Award for International Trade 2021

- Worldwide sales and service support

Struggling to control swivel caster loads?

Are your caster loads drifting out of control? Contact us to discover how you could transform your processes to enhance efficiency and maximize workplace safety with an electric tugger or electric tow tugger.

FAQs: Your questions, answered

The compact design of the MasterHandler provides a tight turning circle, making it perfectly suited to working within tight spaces and moving heavy wheeled loads precisely.

Yes, the MasterHandler range can push, pull, and steer heavy loads weighing up to 14,500 lbs., especially loads that are difficult to control with a tendency to drift during movement.

With the Two Speed Selector switch, ‘Tortoise’ mode enables you to maximize control and operate the machine at a slower speed setting of 1.2kph. In the faster ‘Hare’ setting, the machine’s speed is 3kph.

Machines can be set with custom speed settings where required, with a maximum programmable speed of 6kph.

With adjustable support legs that provide a control point, the MasterHandler can safely control loads with swiveling castors. The MasterHandler prevents the load from drifting, and the hydraulic coupling creates an unbreakable connection between the electric tugger and the attached loads.

Battery performance varies from model to model and is influenced by load weight, battery capacity, environmental conditions, and usage.

Individual battery performance data can be found on the Technical Specification Sheets for each model.

A range of coupling options are available across the range that maximize performance, security, and safety. Custom coupling solutions can also be designed for unique applications.

Yes, the MasterHandler range can work safely on slopes.

When it comes to electric tuggers, it’s important to understand that for every degree of slope involved, the maximum load capacity of the machine is reduced, just as pushing a car on the level requires less force than on a slope. Therefore, if the weight of the load is already close to the maximum capacity of the machine, a more powerful machine may be needed to move the load on a slope.

We carry out a full evaluation of your application to ensure any machine is suited to your needs.

/Images/MH400%201.jpg)