Greener Alternatives to Diesel Forklift Trucks

Material Handling Equipment

In today's world, sustainability is no longer just a buzzword - it's a vital consideration for businesses across industries. As companies increasingly focus on reducing their carbon footprint and operating sustainably, the choice of material handling equipment plays a pivotal role.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Weighing Up Different Options

In this blog, we'll delve into the sustainability benefits of electric tuggers compared to traditional diesel forklift trucks. We'll explore how businesses are prioritizing sustainability, why electric material handling equipment is gaining popularity, and the disadvantages of relying on diesel forklifts – particularly where movements are inside.

The Rise of Electric Material Handling Equipment

With the focus firmly set on cleaner, more sustainable sources of power, leading forklift manufacturers offer an array of electric forklift trucks, stackers and VNA vehicles – with lithium and AGM battery options available. Though for businesses looking for large-capacity equipment, many options still rely on diesel power.

Electric tuggers have gained substantial traction in recent years due to their eco-friendly, safe and efficient operation. With a unique design focused on keeping wheeled loads safely on the ground and maximizing traction, electric tugs can move even the heaviest loads – while retaining a compact design and electric operation.

Unlike diesel or gas-powered equipment, which emits harmful pollutants and greenhouse gases, electric material handling solutions produce zero emissions at the point of use. This shift aligns with the broader trend of electrification in the transportation and industrial sectors, aiming to reduce environmental impact.

Advantages and Disadvantages of Diesel Forklift Trucks

A wide range of diesel-powered forklifts are available on the market. Diesel forklift trucks are often the go-to choice for businesses looking for high-level lifting capacities and the ability to lift heavier loads. With diesel forklift trucks typically featuring higher lifting capabilities than their electric counterparts, they are often used in industries moving products such as heavy plant machinery, construction and industrial manufacturing. Diesel forklifts are well-suited to working outdoors on wet or rough terrain.

While diesel forklift trucks have been a staple in factories moving heavy equipment for years, they come with a significant set of drawbacks that are increasingly problematic when it comes to sustainability and operational efficiency.

1. Environmental Impact:

Diesel forklift trucks are notorious for their environmental impact. They burn diesel fuel, releasing harmful pollutants such as carbon monoxide, nitrogen oxides, and particulate matter into the atmosphere. On average, a diesel forklift emits 5,280-7,920 grams of CO2 per hour from combustion alone. These emissions not only contribute to air pollution but also pose health risks to workers within the factory – particularly where loads are moved inside.

2. Noise Pollution:

Diesel forklifts are typically noisy machines, generating a considerable amount of sound during operation. This noise pollution can be disruptive in factory settings, impacting the working environment and potentially leading to hearing-related health issues for workers.

3. Higher Fuel Costs and Efficiency:

Operating diesel forklifts can be costly due to the price volatility of diesel fuel. These machines are less energy-efficient compared to their electric counterparts, resulting in higher fuel consumption and ongoing operational expenses.

4. Maintenance Requirements:

Diesel forklifts often require more maintenance than electric tugs or electric material handling equipment. They have complex internal combustion engines with numerous moving parts, increasing the risk of breakdowns and necessitating more regular servicing.

5. Carbon Footprint:

The carbon footprint of diesel forklift trucks is a growing concern for companies aiming to reduce their greenhouse gas emissions. The combustion of diesel fuel releases significant amounts of carbon dioxide.

6. Workplace Safety:

The emissions produced by diesel forklifts can compromise indoor air quality within factories. Prolonged exposure to these emissions can lead to respiratory issues and other health problems for employees - leading many businesses to reduce or remove them from their internal operations.

Considering the drawbacks, it’s clear why many factories are evaluating their choices of material handling equipment, with an increasing number opting for the sustainability and efficiency benefits offered by electric tugs and other electric material handling solutions.

Electric Tuggers: Your Solution to Meet Sustainability Targets

Electric tuggers are purpose-designed to deliver the safe movement of heavy loads, offering a safer, more efficient to alternative methods such as manual handling or traditional material handling equipment like lift trucks.

Electric tugs and tow tugs offer several advantages over diesel-powered equipment. As the name suggests, they're electrically powered by rechargeable batteries, eliminating the need for fossil fuels. This not only reduces carbon emissions but also lowers operating costs. Electric tugs are highly manoeuvrable and excel in confined spaces, enhancing operational efficiency.

More Environmentally Friendly Than Diesel Engines

One of the primary drivers behind the adoption of electric tugs is the reduction of a business's carbon footprint. Companies are increasingly setting ambitious sustainability goals, and replacing diesel forklifts with electric tugs is a strategic move toward achieving these objectives. By doing so, businesses can significantly lower their greenhouse gas emissions.

One of our customers at a pre-casting facility in Germany was able to cut 24,000 lbs. of CO2 emissions each year by replacing diesel-powered equipment with our electric tuggers.

Creating Safer Workplaces with Electric Material Handling Equipment

The quiet operation of electric tuggers enhances workplace comfort and safety, making them an attractive choice for businesses committed to sustainability and the well-being of their employees. Large diesel equipment contributes to noise pollution, increasing the risk of hearing issues for employees.

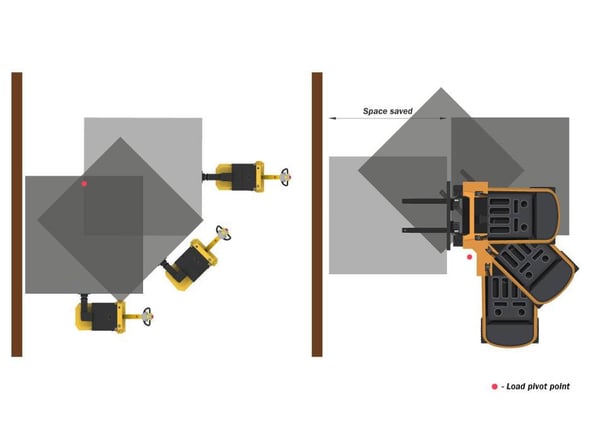

For businesses handling heavy loads, large-capacity heavy-duty diesel forklifts are often used to deliver the power needed to move a load. However, electric tuggers offer a safer, more compact solution to moving the heaviest loads in tight spaces– without compromising on visibility.

Increasing Operational Efficiency

Apart from environmental benefits, electric tuggers offer operational advantages that support sustainability efforts. Their electric motors provide consistent power, while their design maximizes traction, resulting in smoother and more precise material handling. This efficiency translates into reduced energy consumption and cost savings.

Maximizing Your Budget with Electric Tuggers

As well as supporting sustainability objectives, electric tuggers can positively impact budget utilization and cost efficiency. Electric tuggers have significantly lower maintenance costs due to fewer moving parts and no need for fuel or oil changes – and the rising cost of diesel fuel makes electric tuggers a cost-effective alternative in the long run.

Regulatory Compliance

Regulatory bodies worldwide are tightening emissions standards, placing greater pressure on businesses to reduce their environmental impact. Electric tuggers help companies proactively meet these stringent regulations by providing an emission-free solution for material handling.

Choosing electric over diesel not only demonstrates corporate responsibility but also reduces the risk of non-compliance penalties.

The ultimate guide to material handling

Material handling equipment

Looking to understand material handling in a little more detail?

We’ve compiled some helpful resources to get you started.

-

10 Principles of Material Handling Equipment

-

Advanced Material Handling Solutions

-

Forklift Trucks vs. Electric Tuggers

-

Shunters vs. Electric Tuggers

-

Tow Tractors vs. Electric Tuggers

-

Overhead Cranes vs. Electric Tuggers

-

AGVs vs traditional MHE

-

A Forklift-free Future

-

What is Intralogistics?

-

Benefits of Cart Tugger Trains

-

Industrial electric carts

Are you Ready to Transform Your Operations?

The shift toward sustainability in business operations is undeniable, and the choice between electric tuggers and diesel forklift trucks is a clear reflection of this trend.

Electric material handling equipment like electric tugs offer a sustainable, cost-effective, and efficient solution that aligns with both environmental goals and operational objectives. As the world moves toward a greener future, embracing electric tuggers is not only a responsible choice but also a strategic one that positions businesses for success in an increasingly sustainable world.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.