5 Principles of Manual Handling

Manual Handling

As a Health & Safety Manager, you understand the importance of reducing the risk of workplace injuries and accidents. While manual handling is a part of many operations across every industry, it’s an area that contributes to a significant number of injuries worldwide.

Thank you for your request to download the MasterMover 'Manual Handling Checklist'.

We'll also send you an email shortly with your download link included for safe keeping.

If you do not receive the email, please let us know at salesteamusa@mastermover.com.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Understanding the 5 Key Principles of Manual Handling

Remapping tasks, utilizing supporting equipment and providing comprehensive manual handling training can help avoid or reduce manual handling in many processes. However, it is not always possible to avoid manual handling tasks completely.

To minimize the risk of injury and maximize safety, there are 5 key principles to consider. In this blog, we'll cover what these principles are, how they apply to your work environment, and how to implement them into safe manual handling practices.

The Risks of Manual Handling

Manual handling activities can present the risk of injuries such as strains, musculoskeletal disorders and other injuries. The risk of injury increases when hazardous manual handling tasks are repetitive, awkward or involve moving particularly heavy loads.

5 Principles of Manual Handling

It is not always possible to avoid manual handling activities and tasks. Alongside comprehensive manual handling training, risk assessment procedures and the use of supporting equipment, the following five key principles can be used to reduce the risk of manual handling injury.

Thank you for your request to download the MasterMover 'Manual Handling Checklist'.

We'll also send you an email shortly with your download link included for safe keeping.

If you do not receive the email, please let us know at salesteamusa@mastermover.com.

-

Plan

Before undertaking manual handling (whether that's lifting, pushing or pulling a load), ensure that your path is clear. Check for obstructions and ensure there are no trip hazards or slip risks.

When planning a movement, it's important to assess if the task is feasible. Staff should avoid moving heavy loads that exceed their abilities, and instead, use a supporting handling aid such as an electric tugger, pallet truck or other material handling equipment.

-

Position

When making a movement it is important to establish a good posture and position. Center your body and feet correctly, keeping your feet apart for maximum stability.

Avoid twisting and do not bend your back or lean forward. Awkward posture or incorrect positioning can increase the risk of musculoskeletal injury and put excess stress on your back. After establishing a stable position, ensure that you firmly grip the load being moved.

-

Pick

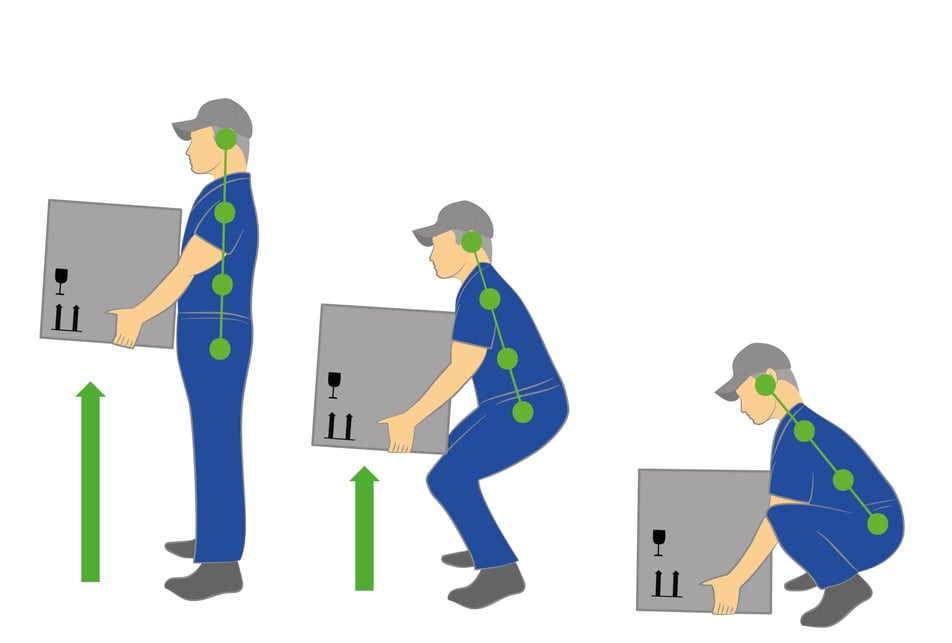

Again, this involves maintaining a good posture. When lifting a load, keep the load close to your body and use your legs to lift it - making sure not to strain your back.

-

Proceed

Keep the load close to your body during movement to reduce the risk of bending or straining your back. Whether you are lifting an item or pushing a wheeled load, keep your head and spine upright and avoid twisting.

-

Place

When you lower an object after lifting, bend your knees and use your leg muscles to lower the load. Smooth movements are essential to preventing strains or injury.

Manual Handling Tasks - Pushing and Pulling

When people think of manual handling, they often think of lifting tasks.

However, manual handling also covers activities like moving heavy-wheeled loads, so it’s important to remember that pushing and pulling loads can also result in the risk of injury.

Across a range of manual handling operations and tasks, supporting mechanical aids and handling equipment such as lifting equipment and electric tugs can be used to reduce the risk of workplace injuries and facilitate safe moving and handling of loads.

The Importance of Correct Manual Handling Techniques

Alongside applying safe manual handling principles, control measures such as using mechanical aids and following robust manual handling risk assessment processes, correct manual handling techniques are crucial to ensuring the safe movement of loads and reducing the risk of injury occurring from manual handling.

When lifting a heavy load, following a safe manual handling technique is crucial.

- Lift with your legs, not your back

- Keep the load close to your body

- Maintain good posture

- Take breaks when necessary

Using Mechanical Aids to Reduce Workplace Injury

Where tasks have been assessed using the 5 principles of manual handling but present a risk of injury, businesses should look to utilize a mechanical aid to improve safety.

For lifting loads, this may involve hoists, pallet trucks, forklift trucks or vacuum lifters. Electric tuggers and powered tugs can be utilized to deliver the safe movement of wheeled loads.

Your guide to manual handling

Manual Handling

Dive into our comprehensive guide covering everything you need to know about manual handling.

Electric Tugs: Your Manual Handling Aid for Moving Wheeled Loads

Safety Managers across the globe trust MasterMover electric tugs to reduce manual handling. Eliminating the manual effort required to move heavy loads, electric tuggers put operator safety first. Bringing both comfort and power to repetitive tasks, our electric tuggers make it easy to transport heavy loads while reducing aches and strains.

SmartMover

Small but mighty

Compact yet powerful - our SmartMover range helps you give manual handling the push.

MasterTow

Simple, reliable towing solutions

Explore our MasterTow range for a simple and reliable alternative to manual handling.

MasterTug

Push, pull and steer with ease

Unlock the effortless maneuverability of heavy loads with the MasterTug range.

Looking to Remove Manual Handling Risk & Reduce Injuries?

We’ve created an easy-to-use checklist to help you quickly assess manual handling processes and identify the next steps in reducing the risk of manual handling injuries.