Continue reading

Continue reading

Safer rail handling solutions

Rail & Rolling Stock

For rail maintenance depots and rolling stock manufacturers, electric tugs and electric pushers improve safety and efficiency in moving loads such as bogies, wheels and carriages.

Moving heavy loads – the answer isn’t manual handling

Whether it’s in manufacturing or maintenance of rolling stock, handling heavy loads is a challenge in the rail industry.

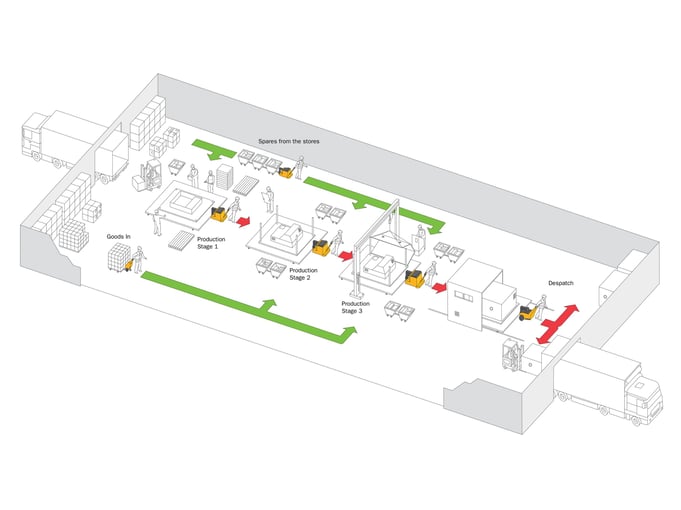

For manufacturers, streamlining production is crucial, and any material handling equipment needs to support this whilst also prioritising safety.

Likewise, for maintenance providers, relying on several engineers to push heavy bogies and wheelsets by hand results in safety issues and reduces efficiency.

Safer, simpler movements for the rail industry

Electric tugs and pushers enable rolling stock manufacturers and maintenance providers the ability to move heavy loads with ease.

Whether it’s the movement of carriages through production or the transfer of bogies into shot blasting in the maintenance shop, electric tugs guarantee the safe, controlled movement of load – maximising efficiency and improving workplace safety.

The benefits of electric tugs in rail and rolling stock

Compact, easy-to-use designs enable operators to safely move heavy rolling stock.

With an emission-free design, electric tugs are ideally suited to working inside manufacturing facilities and workshops as well as facilitating efficient building-to-building movements.

-

Eliminate manual handling

Make the movement of heavy loads a one-person job without compromising on safety – electric tugs reduce the risk of injuries and boost productivity.

-

Reduce downtime

Streamlining the movement of heavy in the rail industry, electric tugs increase operational efficiency and reduce downtime.

-

Purpose-built for moving rolling loads

Designed to move wheeled and rolling loads, use the right tool for the job. Electric tugs reduce safety risks and the misuse of forklift trucks and shunters.

Our range of rail & rolling stock moving electric tugs

AllTerrain

Up to 5,000 kg

Delivering powerful performance in demanding conditions, choose the AllTerrain range to safely move heavy loads on rails and castors.

MasterTug

Up to 20,000 kg

The MasterTug range allows a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to 20,000kg.

MasterTow

Up to 20,000 kg

Drive safety and efficiency with our powerful electric tow tugs, designed to safely move loads of up to 20,000kg.

Trusted by leading rolling stock manufacturers and maintenance providers

The biggest names in the rail industry trust MasterMover’s electric tugs to safely move loads, driving operational efficiency and improving workplace safety.

The beauty of the MasterTug is it’s ease of use, it’s serviceability and its compact proportions, which means it can be used productively inside our premises without taking any further space.

Simon LedgarSkopos

Your Questions, Answered - FAQs

- Bogies

- Axles

- Wheelsets

- Carriages

- Wagons

- Transformers

Electric tugs and electric pushers are used across the manufacture and maintenance of rolling stock to safely move loads such as:

No, unlike lifting equipment such as forklift trucks and cranes, an electric tug does not require a license to operate. A license-free operation reduces downtime and maximises operational efficiency, reducing wasted time waiting for a licensed driver.

Minimal training is required to safely operate an electric tug and we offer training packages to suit every requirement.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving.

Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

A range of coupling options are available across the range that maximise performance, security and safety.

Custom coupling solutions can also be designed for unique applications.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

New Electric Tugs To Create Flow Line Production Systems