Material handling electric tuggers

Batteries & Charging

Everything you need to know about electric tugger batteries and charging

Electric tow tugs are a type of battery-powered industrial equipment designed to move heavy-wheeled loads in various environments, from retail to biopharmaceutical manufacturing.

As with any electrical equipment, electric tow tugs and their corresponding batteries and chargers are understandably a key area of interest to potential operators.

In this blog, we’ll cover the key questions when it comes to batteries, charging, and runtimes.

What influences battery life?

Like any battery, the battery life of an electric tugger or electric tow is determined by usage, specification, and environmental factors.

Battery life can be influenced by variables such as:

Load weight and route

Run speed

Battery specification/size

Environmental conditions

How long does the battery last on an electric tugger?

While several factors influence battery life quite significantly, the below gives you an idea of the battery life for some of our electric tuggers.

The battery life for electric tuggers is quantified in miles to show the distances the units can travel on one charge.

To give you an idea about the battery life you can expect from an electric tugger, we’ve included the battery life for some of our key models below.

The figures below are based on test conditions of:

- A continuous movement of 75% of the rated maximum load weight

- Use on a flat, painted concrete floor

- Running at 1.86 mph

- Battery discharge down from 100% to 30%

SM100+

Maximum load weight: 2,600 lbs.

Battery pack capacity*: 22Ah

Distance*: 4.78 miles

TOW300

Maximum load weight: 6,600 lbs.

Battery pack capacity*: 73Ah

Distance*: 6.52 miles

MT600+

Maximum load weight: 13,000 lbs.

Battery pack capacity*: 102Ah

Distance*: 5.22 miles

TOW1000 ES

Maximum load weight: 22,000 lbs.

Battery pack capacity*: 204Ah

Distance*: 6.34 miles

MT1500+

Maximum load weight: 33,000 lbs.

Battery pack capacity*: 179Ah

Distance*: 4.03 miles

PS3000+

Maximum load weight: 30,000 kg

Battery pack capacity*: 120Ah†

Distance*: 4.0km

* Standard AGM battery

† 48v pack

What batteries are available?

Many machines within our product portfolio have multiple battery options ranging from standard maintenance-free AGM batteries, to upgraded performance batteries and lithium options.

Across the range, most machines have an interchangeable battery design that enables operators to interchange AGM battery packs for a 24/7 continuous operation. This involves having a spare battery charged and ready to go (Note: Lithium batteries are not interchangeable).

Lithium batteries are available on many models within our range for applications where charging can only take place in short, sharp bursts. Lithium batteries allow operators to charge the batteries for short periods (known as opportunity charging) and are a perfect solution for high-intensity operations.

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

This is a modal window.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

How long does the battery take to charge?

Recharge times for standard AGM batteries are typically between 6-8 hours, with these timings based on recharging from 30% to 100% on standard batteries.

Alongside the benefit of opportunity charging, lithium batteries have significantly faster recharge times than lead-acid batteries, often this is between 1-4hrs.

What types of chargers are available?

Internal and external charger options* are available across the range for maximum flexibility. A MasterMover representative will always specify the appropriate battery and charger combination to maximize performance and ensure longevity.

(*Note: Lithium batteries are only available with external chargers.)

How big is the charger?

Charger sizes vary depending on the specification but, as a rule of thumb, electric tugger chargers are about the same size as an A4 piece of paper.

How do I know when to charge the battery?

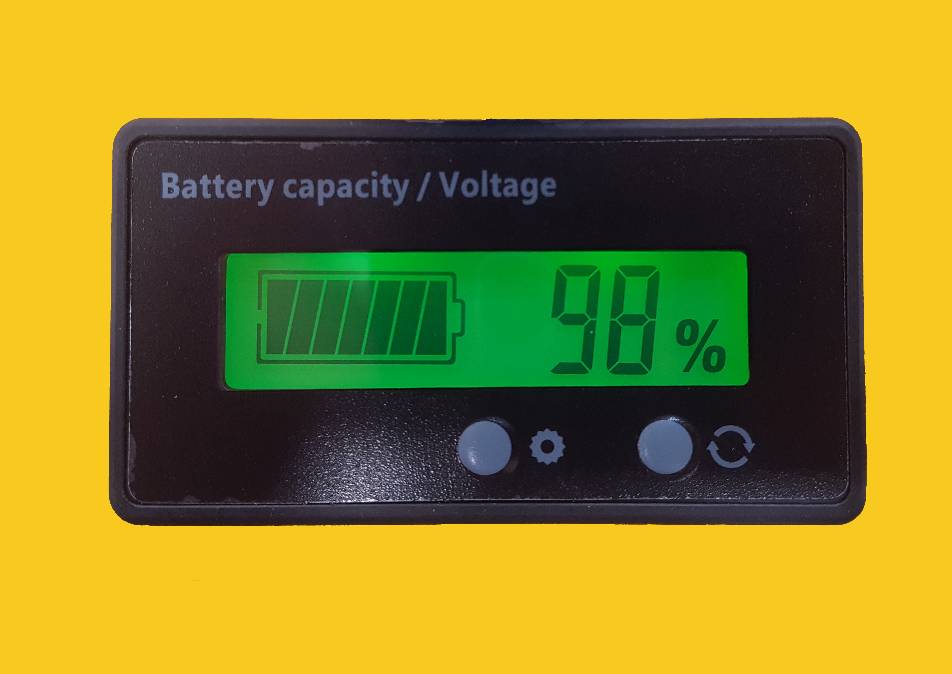

Electric tuggers are fitted with a Battery Discharge Indicator (BDI) which displays the charge level of the battery pack as a percentage. This gives operators a quick visual reference of the remaining battery life percentage along with 3 light indicators (green, yellow, and red).

When the battery needs charging, the BDI will display a yellow light, indicating that the battery should be charged as soon as possible. To maximize battery lifespan and performance, all batteries should be charged before the Battery Display Indicator shows 30% or less.

What is the ‘Battery Protection System (BPS)’?

An optional Battery Protection System (BPS) is available to protect the battery from misuse and prevent battery damage.

On reaching a battery life of 40%, the machine will slow to just below 1.24mph, highlighting to operators that the equipment needs to be charged.

At a battery life of 35%, the machine will slow further to approximately .62mph, at which point the machine must be charged.

The BPS system protects the integrity of the battery by forcing operators to charge the machines at the correct battery interval and depth of discharge, protecting against battery misuse and damage.

Keeping your loads moving

With a range of machines available and different battery power options, our electric tow tugs are designed to ensure they are ready to get to work whenever they are needed.

Whether you have an application requiring infrequent, occasional movements, or a high-usage environment, a battery-powered electric tugger is a dependable solution.

The ultimate guide to electric tuggers

Electric tugger essentials

Looking to understand electric tuggers in a little more detail?

We’ve compiled some helpful resources to get you started, covering everything from how they work, different types of batteries, getting the right connection point and more…