The Ultimate Tugger AGV Guide from Automation Expert, James Jones

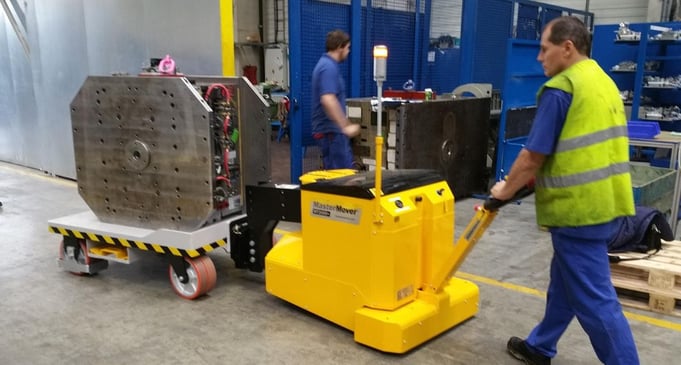

Tugger AGVs (Automated Guided Vehicles) are becoming an essential tool for businesses looking to enhance efficiency and streamline operations. By automating repetitive towing tasks, these vehicles allow companies to optimise workflows, reallocate ...